How Used Equipment Can Save You a Staggering Amount of Time and Money

Projects completed in a fraction of the time for a fraction of the cost. It sounds too good to be true, but it’s possible by leveraging the used equipment market, as IDI has recently done for some of our clients.

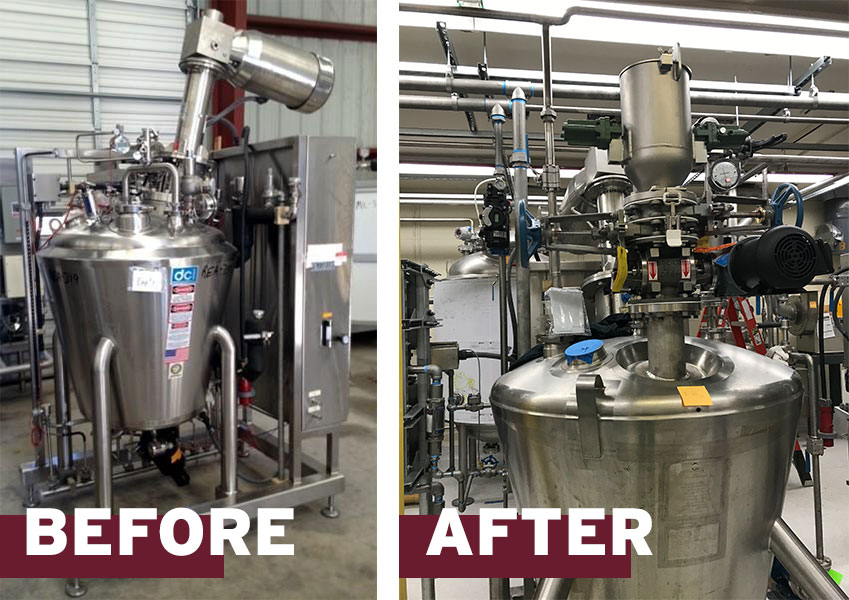

In the two most recent cases, a supplier to Oak Ridge National Laboratory and a CBD manufacturing operation were developing new chemical processes. We did the usual engineering of defining what the process was going to be and establishing the heat and material balances to size the equipment. The delivery schedule for the required equipment, purchased new, was running 9 to 12 months. To shave that down, we turned to companies that handle high-quality used chemical and pharmaceutical equipment, assessed what they had and how it would fit into the processes, and determined what modifications would be required. The 5 standout points of this approach:

1. Time: Used equipment can be delivered almost immediately. Once it arrives, modifications will need to be made. At IDI, we use our laser scanner to detail each piece and what needs to be modified and develop modification detail drawings. Thanks to our relationships with local fabrication shops, we are able to get bids, select a shop, and turn a piece around in less than 3 months.

2. Price: The savings can be eye-popping. In one case we purchased a piece of used equipment for $25,000 that would have cost $295,000 new. The redesign and modifications cost no more than $15,000, meaning the final cost was not quite 15% of what the sticker-price of the new equipment would have been. Not all savings are that dramatic, but they are significant.

3. Relationships: At IDI, we have a deep knowledge of equipment and the companies that sell it used. In many cases the item we need may not be something they have publicly listed on their website. Our ability to communicate what is needed and the level of personal relationships we have allow us to access the equivalent of what an “ideal design” would be and put it to use through slight modifications.

4. Quality: …is not a concern. It is typically guaranteed by the dealer and we generally request the original design prints. The specifications tell us much of what we need to know, and we do an in-depth safety review to make sure the equipment can handle what we need, from ensuring it has the proper thickness to the proper pressure ratings.

5. Projects of a shorter nature: This approach has proven to be perfect for clients who are considering a short-term project, such as a test project. When it is not necessarily a process that’s intended to run forever and you don’t want to put millions into buying equipment, going this route can allow you to get up and running quickly for much less.