The Small Projects That Can Make a Big Difference

Sometimes the small projects are the ones that make a real difference. Something as specific as designing a new structural platform or modifying an existing one can give your employees a better and safer way to access a piece of equipment. But the seemingly easy things can end up being the toughest to get done.

That’s because many large engineering design consulting firms are just too big for the small stuff. Because of their overhead-heavy nature, they typically won’t take jobs priced below $10,000 because the numbers don’t work for them. That’s not the case with IDI, and we wanted to spotlight some of the small jobs we typically undertake for clients—those projects typically in the $3,000 to $8,000 range—that we see as having an impact that can be larger than the effort or dollars behind it.

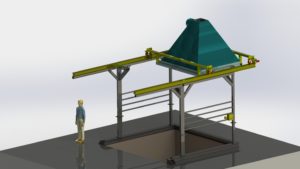

These projects run the gamut from relocating utilities and installing fall protection systems to addressing corrosion issues. In one case, a client was looking to locate an HVAC system on the roof but didn’t know if it could handle the load. In another case, a design of new guarding was needed to protect workers on both the drive and tending side of a paper machine. Another client needed a design and drawings for a ladder and platform in order to access sensors mounted above a conveyor. We’ve also been tasked with relocating and designing new material handling ductwork and chutes around a new conveyor configuration.

More than anything else, they are things that need to be done to keep a plant running efficiently day in and day out. By tackling them, our clients head off future equipment issues and downtime. There’s real value in that.