Your next process project – why starting with those PFD’s and P&ID’s is the way to go.

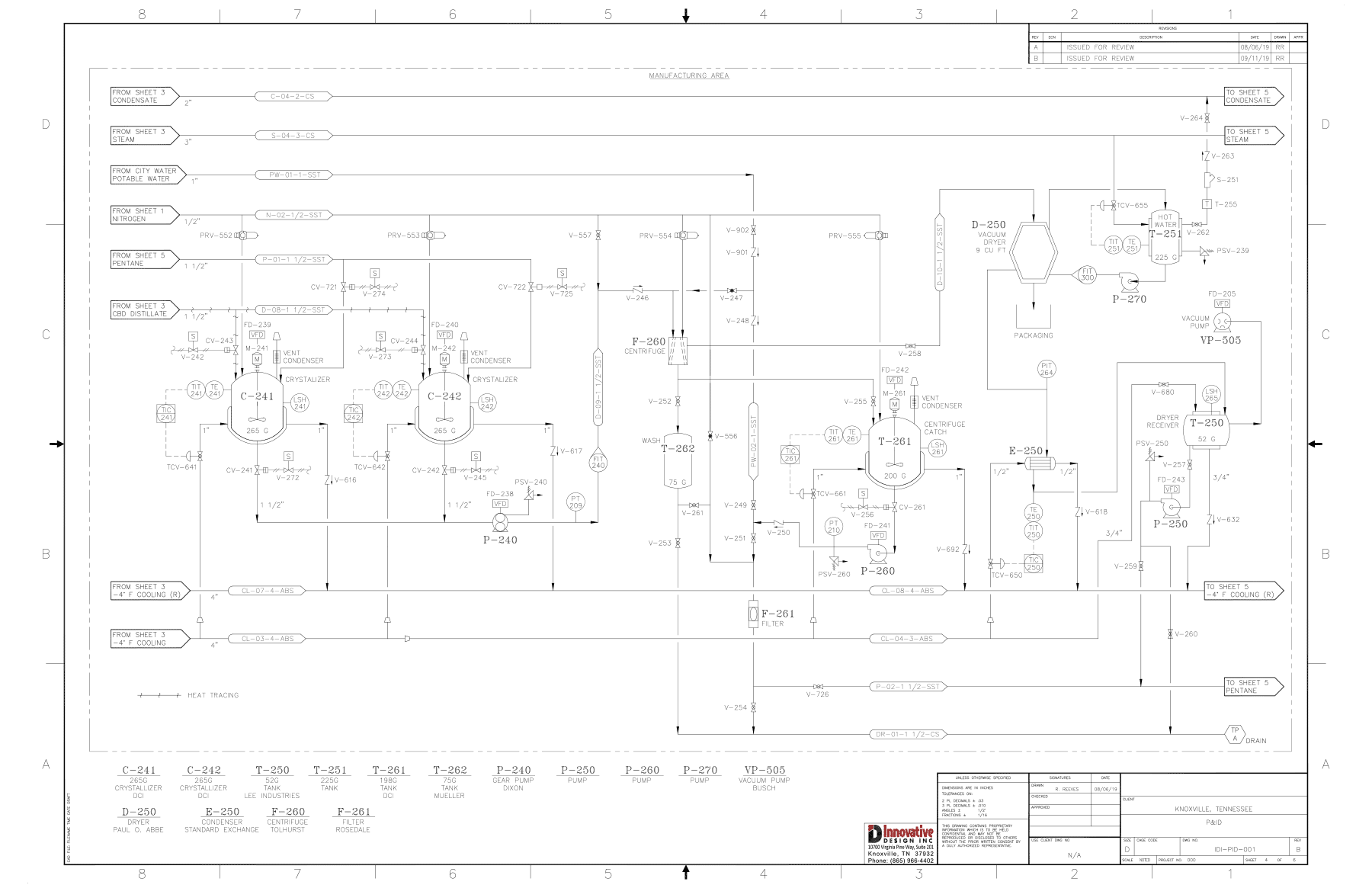

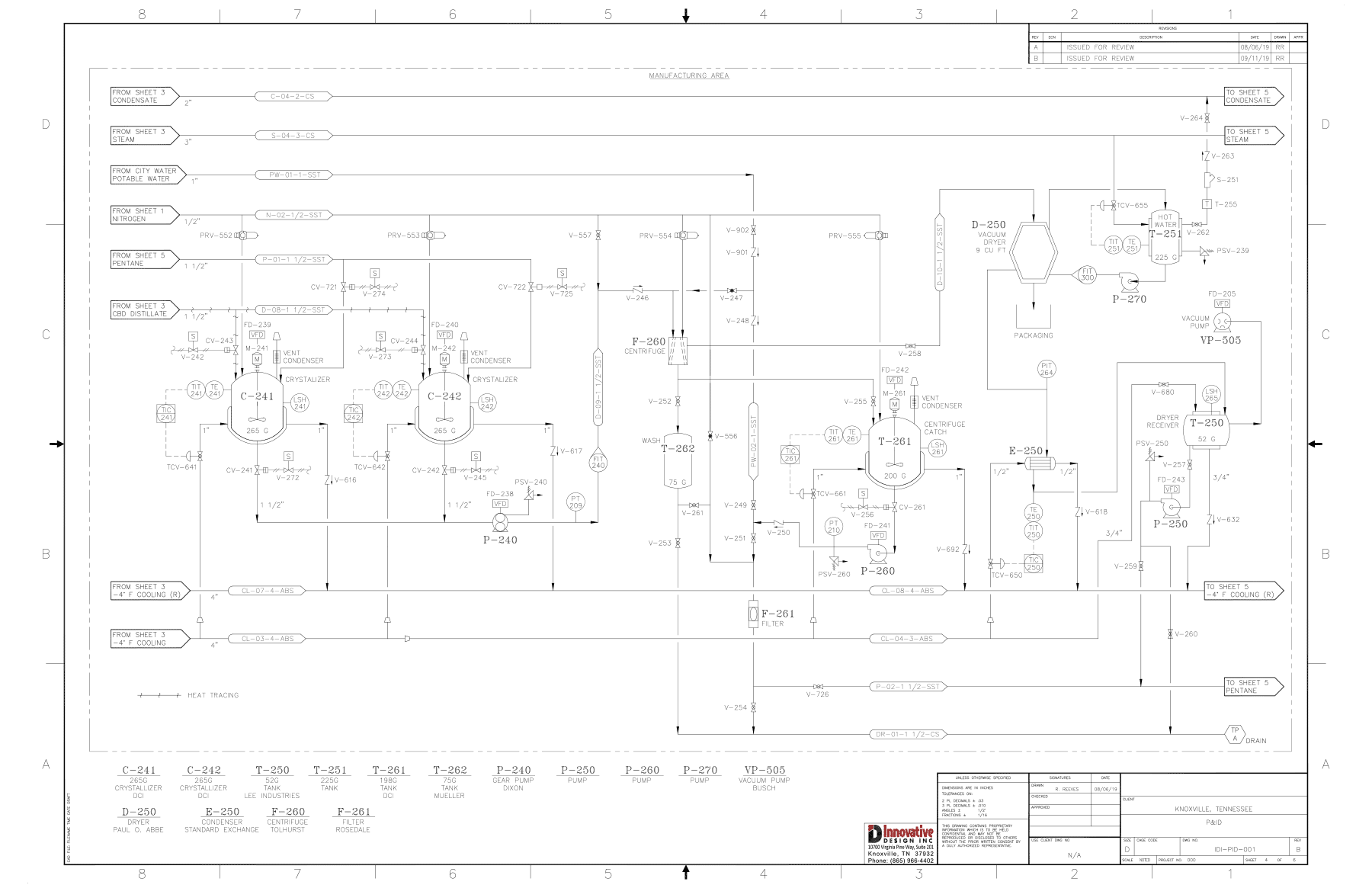

OK, you are starting a new process project, and you need to get the project team to agree on the process purpose, what equipment is required, what plant utilities are needed, are they available, what are the budgetary estimates and what permitting is required. The starting point can be daunting but using a Process Flow Diagram (PFD), and a Piping and Instrumentation Diagram (P&ID) makes your job easier. It allows the project to start off on the right foot – organized.

A basic PFD identifies problems with the process early on and helps drive the project in the right direction. In single line diagram, it clearly identifies what goes into the process, what comes out, and all the major components required in between. Budget is always a key factor in any project and by using some early engineering hours to develop a comprehensive PFD and a P&ID, a budgetary estimate can be developed for the whole project. Also, determining what permitting might be required early on is very important. For example, if the project is in a new location, and if you are required to adhere to zoning requirements, you may need state permitting for boilers and/or pressure vessels and may even need environmental permitting. Before any permit applications are evaluated, a PFD is required.

Once the PFD has been developed, it provides a baseline for what equipment and instrumentation is needed. Using the baseline PFD, engineers develop the P&ID, equipment selection and specifications, valve and instrument selection, and pipe sizing. Ultimately, a well-developed P&ID serves as the road map as the project moves into the design phase.

Any experienced process designer will tell you at length why their jobs are made so much easier by beginning a process design with the P&ID, the road map. It provides clear direction from the beginning. Without it, the project can quickly become disorganized, thus creating additional cost due to continual rework.

Next month: From concept to fabrication, and ask a process designer what he thinks about that P&ID?