Project

Municipal Wastewater Treatment Plant Expansion

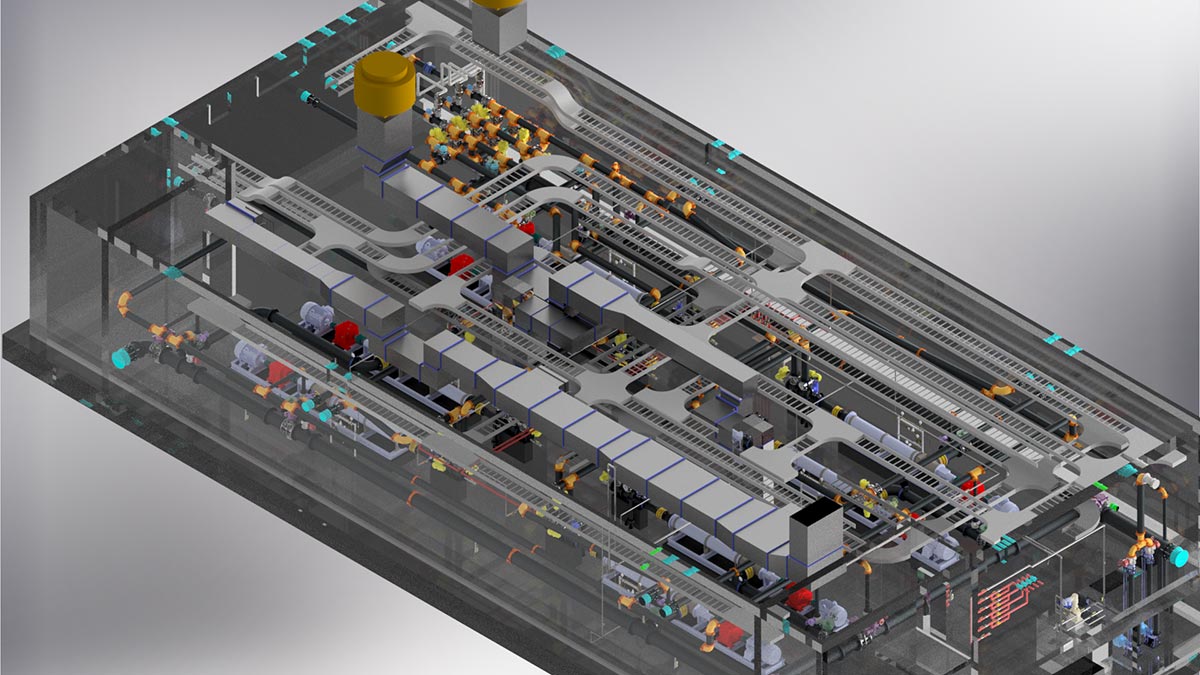

Cities large and small have wastewater treatment facilities serving their communities. With growing populations and increased regulations, upgrades and plant expansions are a necessary part of wastewater plant operations. IDI was contracted by an Ohio construction company to work on a project to develop a 3D piping model, fabrication details, and installation diagrams for a wastewater plant doing just that, expanding to meet the growing demand for more wastewater services.

Utilizing a 2D concept and P&ID (Piping and Instrumentation Diagram) provided by the customer, the IDI engineering and design team began the design by creating a 3D model of the existing structures and new piping systems for the plant. There were multiple piping systems being incorporated into the existing plant, as well as the new expansion. It was vital to understand the preliminary concept and its relationship to the existing structures. The IDI team mapped out how the multiple piping systems would fit into the current envelope and make the critical connections to existing equipment. There were multiple obstacles to work around, such as HVAC ductwork, cable trays, electrical panels, columns and walls. Some interferences were found, as is common during the modeling process, and the design was modified.

The piping systems consisted of pipe spool pieces in PVC, ductile iron and stainless steel, and included pumps, valves, flow meters, auto strainers, grinders and mechanical joints. There were a wide variety of sizes and components ranging from small bore pipe to 16” pipe. An important part of the project deliverable was to provide a detailed Bill of Materials (BOM). The 3D model was created piece by piece so that the BOM would automatically generate with unique part numbers for each item in the piping systems. This allowed for easy ordering, shipping, and managing of the components on site. Detailed installation drawings were also created from the 3D model for each piping system showing the part numbers and layout of the components.

By creating an accurate 3D model, the new systems matched up to existing structures and connections, included complete BOM information for procurement and inventory control, eliminated the need to cut or modify pipe in the field, avoided interferences, and aided a smooth installation.