Project

A New Process for a Leading Paper Manufacturer

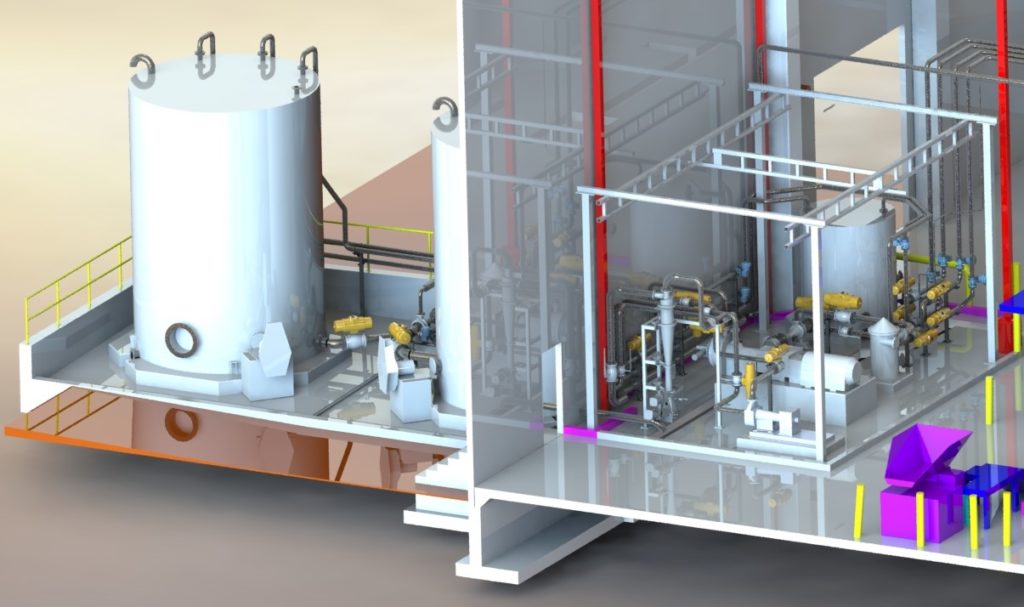

A leading paper manufacturer had a money-saving idea and needed IDI to help determine it if it would truly raise the bottom line. The company had developed a process for using a cheaper supply stock known as printed broke in its paper manufacturing but needed to determine the return on investment, which meant developing drawings that would allow them to price the project. It was an effort that covered IDI’s bases of expertise: laser scanning, mechanical process piping design, structural design, and a lot of brainstorming with the client.

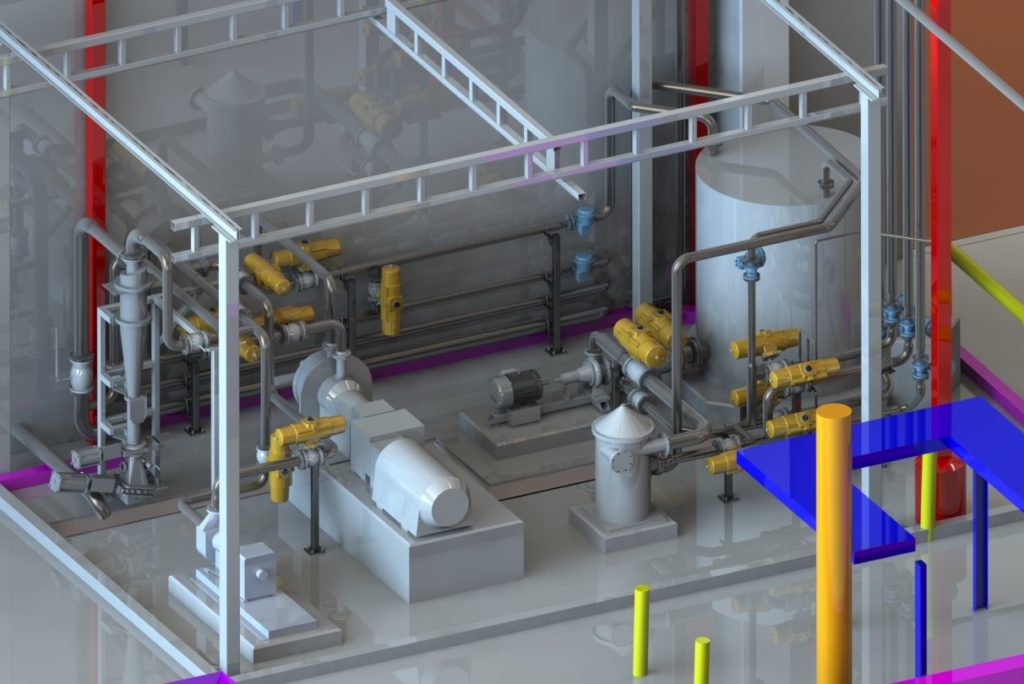

IDI began by laser scanning the chosen area and modeling the adjacent equipment. Using the client’s initial diagram of the process, IDI created a design that was as compact as possible and took maintainability into account: allowing for adequate space around the equipment, making sure the valves are at accessible heights, and incorporating a bridge crane that could be used to retrieve a motor or pump. After several rounds of adjusting the design to align \the client’s needs with what was possible, IDI provided detail drawings of the equipment layout, tank fabrication, piping and supports, equipment foundations, and drains.