Project

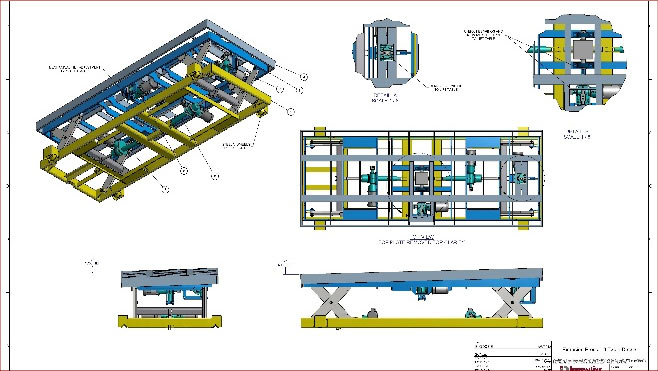

Designing a Highly Flexible Extrusion Press Positioning Table

Meeting challenging conditions in aging facilities is just what IDI did when designing this extrusion press positioning table. The table needed to be flexible and close to the ground, as the shape of the extrusions handled are variable, the presses are not plumb or level, and the billets handled by the table could weigh up to 10,000 pounds. IDI met those conditions by designing a positioning table that has up to 2 inches of flexibility in all directions, a 2-foot lift height, and a 2-foot lateral motion in and out for billet extrusion retrieval.

IDI used a dual scissor lift design to meet the collapsed height requirement along with providing the full extension needed to meet the billet as it is ejected from the extruder. The table’s motors are designed to integrate with the plant’s PLC system and are adjustable for each different billet run. IDI also integrated motor brakes and bolt on billet guides for safety.