Articles

What to Look for in a Designer Candidate, Beyond the Software

Last month we described the trade of design, utilizing experience and knowledge of the field, in addition to being able to utilize the CAD software. This month we will point out some things we look for in a designer candidate that sets them apart, hopefully leading to a successful hire. First on the list, a […]

The Trade of Design – It’s More Than Learning the Software

Part 1 of a 2-part series It’s one thing for a drafter to have training and experience with CAD software such as Solidworks, Inventor, Creo, Autocad, etc., but it’s quite another to have the “design” training and experience. The software is merely the modern-day tool of the trade. Most people who choose the field of […]

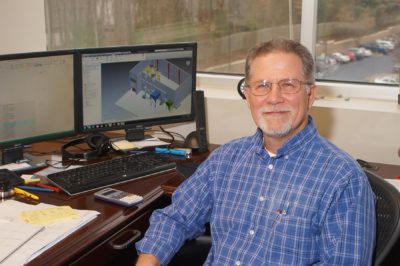

Utilizing the accomplished veteran’s knowledge through mentorship

Recently a statistic was published by the NNSA on www.energy.gov that stated “40% of the workforce for NNSA (National Nuclear Security Agency) will be eligible for retirement within the next 5 years”. Those individuals have a wealth of knowledge that will become lost. Therefore, mentoring should be an important practice in every organization. The goal […]

Communication – From concept to fab details, why keeping your customer involved is so important

I have heard it too many times when working with a new customer: “The company we used previously just didn’t communicate, we ended up with an engineering design that didn’t match our needs or expectations.” The customer finds themselves with poor results because the engineering firm didn’t keep them involved from the beginning. Especially during […]

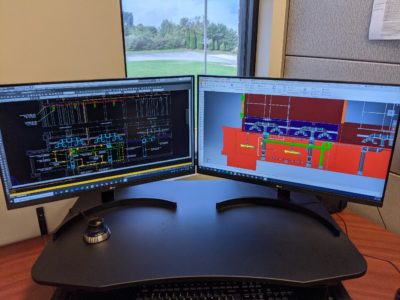

Tight Footprints Lead to Tight Clearances, but is it Maintainable?

When deciding on a new installation, space is always at a premium. The balance between available space and the ability to maintain a system is a delicate proposition. There is an old belief that “the designers and engineers have the project for a year, but maintenance has to live with it for the project’s lifespan”. […]

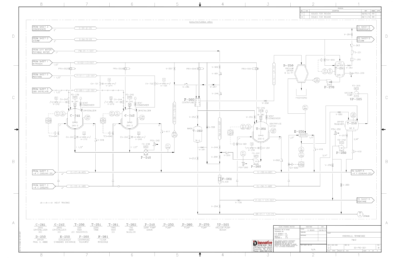

From concept to fabrication, ask a process designer what he thinks about that P&ID?

In last month’s article: “Your next process project – why starting with those PFD’s and P&ID’s is the way to go”, we looked at why a Process Flow Diagram (PFD) is the first step, and why and how it evolves into a Piping and Instrumentation Diagram (P&ID) to help ensure a successful project. This month, […]

Your next process project – why starting with those PFD’s and P&ID’s is the way to go.

OK, you are starting a new process project, and you need to get the project team to agree on the process purpose, what equipment is required, what plant utilities are needed, are they available, what are the budgetary estimates and what permitting is required. The starting point can be daunting but using a Process Flow […]

The Benefits of 3D Laser Scanning—According to an IDI Client

It’s one thing for us to tout the long list of benefits that our 3D laser scanning capabilities bring to the job. It’s another to hear it straight from the client. Bob Uncapher, the former resident engineer at 3M’s plant in Midway, Tennessee, reflected on a time when IDI and 3D scanning played a crucial […]

Why Every Engineer Should Pull a Few More Seats to the Table

One of the best things an engineer can do after engaging an engineering firm is pull a few more seats to the table. At IDI we stress the need to incorporate the end users and their perspective from the get-go. That means bringing floor managers and maintenance personnel into each project. Too often engineering firms […]

Nothing Triggers a Headache Like a Bad Drawing

The devil is in the details—especially if those details are a mess. There’s a big difference between a well-done drawing package and a not-so-well-done package. The former can make things so much easier for an engineer and their fabricator/constructor. The latter can cause a major headache, which is why it’s so important for an engineer […]